By Tim E. Hovey

Whether you’re a casual hunter or someone that squeezes every hour out of the hunting season, hands down the most used firearm in your safe will most likely be your shotgun. For you pump gun enthusiasts, cleaning your shotgun is easy to do. A quick tear down, a few squirts of gun oil and you’re good to go. Honestly, when I used a pump shotgun, I would do this maybe once a season, if that. The pump shotgun mechanisms are simple and easily taken care of. The same cannot be said for autoloaders.

Semi-automatic shotguns are more complex in their design and rely on smooth gas operation to auto advance the next shot into the chamber. Essentially the gases released from one fired shell works the action, ejects the hull and advances the next shell. As you can imagine, the intricate pieces that make all this happen need to be clean and lubed sufficiently.

I found out about the cleaning difference between the pump action and the auto loader the hard way, when I graduated to the auto loader about 15-years ago. I had purchased a Browning Silver Hunter a few months before the mourning dove opener back in the early 2000’s. To get used to the shotgun before the bird season, I took it out several times to shoot clay targets and to chase rabbits.

The evening before the dove opener, I loaded up the new shotgun and added my tried-and-true Remington 870 pump action as a backup. The new browning probably had 6-8 boxes of shells run through it before the season and hadn’t been cleaned. Up until then, it had been running smoothly.

The morning of the hunt, I started having issues with the Browning. It first would stove-pipe hulls in the action without advancing the next round. Then it started not even attempting to eject the spent shell. That morning, I couldn’t shoot three shells in a row without having an issue. I grabbed the Remington and finished the flight.

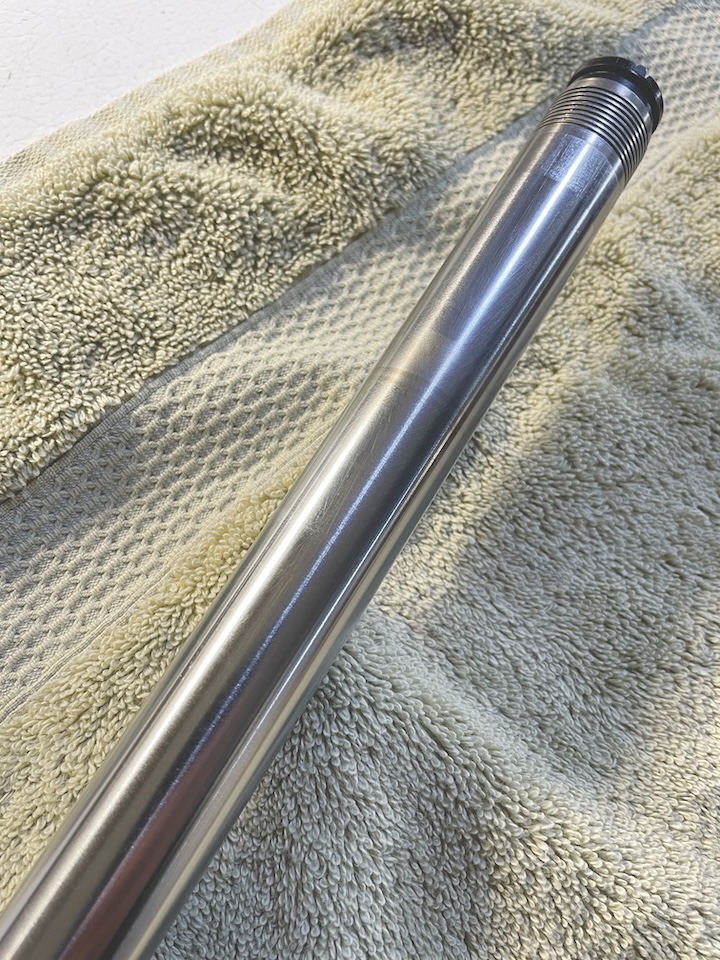

Back home, I referenced the owner’s manual and took down the Browning. I was completely shocked at how dirty it was. The compensator, the piece that redirects a portion of the propellant gases to counter recoil and to work the bolt to eject the spent hull and advance the next shell, was filthy. The part also did not slide smoothly on the cartridge tube, causing issues with ejecting and advancing.

That evening, I tore the entire firearm down, cleaned it and oiled up the appropriate parts. As I tried to reassemble the shotgun, I ran into issues. Unfamiliar with all the parts, I knew early on I needed some help. A quick visit to YouTube and viewing a Silver Hunter cleaning video and I was back on track.

Feeling like I had a solid benchmark of running 6-8 boxes of shotgun shells through the Browning before it needed a good cleaning, I set that as the maintenance schedule. As I continued to use the Silver Hunter, I would find that it required a bit more cleaning than that.

I started carrying a can of Hoppe’s Number 9 cleaning fluid with me on every hunt and got used to stripping down the Browning in the field if it needed a cleaning. I got so used to tearing it down, that I began cleaning the shotgun after every other trip. Maintaining this cleaning schedule has put stove piping and jams completely behind me. It took a few seasons, but I began to understand that with the luxury of auto loading shotguns comes the chore of regular cleaning maintenance.

Maintaining smooth auto loading performance all comes down to routine cleaning. If you’re having issues with stove-piping or cartridge jams, the shotgun likely needs a good cleaning. I’ve also discovered that cleaning and oiling the bolt and trigger assembly, and greasing the appropriate parts will leave you issue-free in the field.

If you’re done hunting for the season, spend some time cleaning your firearms and oiling them up in preparation for later this year. Taking care of them in the offseason will ensure that they take care of you when you flush that covey or draw down on a committed group of mallards. Cleaning is caring!