BY STEVE COMUS

Casual shooters need not feel left out if they don’t reload. But highly committed shooters and those who want to shoot firearms that are chambered for wildcat or obsolete cartridges are well advised at least to consider loading.

Although it is true that reloading ammo CAN save money, it is also true that it takes a considerable investment up-front to get into the reloading game.

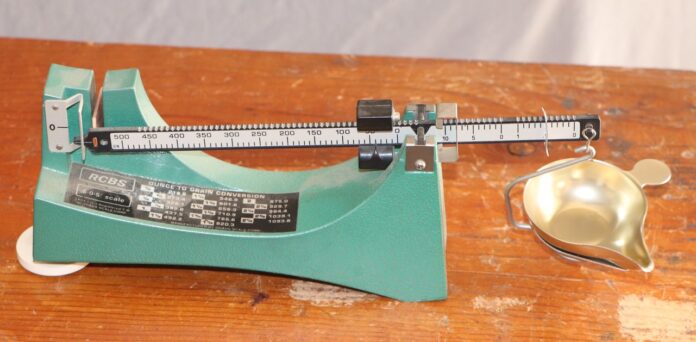

For example, minimally, reloading for metallic cartridges requires a press, dies, shell holder, scale, caliper, case trimmer and chamfering tool. For shotshells, the press usually includes the dies and a shell holder is not necessary.

Regardless the type of ammo, components like powder come in containers of one or more pounds, bullets and primers come in multiples of 100 and shot comes in 25-pound bags.

New cases can be purchased, but most cartridge cases that are reloaded are empties from when factory loads were fired once and then reloaded.

The number of reloads from an individual case ranges from once to more than a dozen times, depending on factors like pressure.

The bottom line is that it takes a minimum of hundreds of dollars to get into the reloading game. Because of the many gadgets and goodies that are handy when reloading, that amount can quickly go to $1,000 or more.

There is no effort here to scare away potential handloaders with sticker shock because, in the long run, the up-front investment becomes a savings over time for those who shoot regularly, or at least significantly, or those who want to shoot cartridges that are not generally available on the open market.

For example, the only way to keep shooting a gun that is chambered for obsolete cartridges is to load for it. Often, this also calls for forming the cases from other readily available cartridges, which involves even more dies, sizing lubricant, etc.

A case in point is that to keep shooting an 1886 Winchester lever rifle chambered for .33 WCF (Winchester Center Fire) is to form cases from .45/70 Govt. brass and then load.

Incidentally, that rifle/cartridge combination was a favorite of Ben Lilly, the legendary bear hunter in the southern Rocky Mountains of New Mexico in the late 1800s and early 1900s. It was fulfilling for me when I used my .33-caliber ’86 to take a big black bear in the area where Lilly hunted those many years before.

The basic loading press for metallic cartridges is the single-stage press where each step of the process is done sequentially, changing dies for the individual steps.

Also, there are progressive presses that hold all of the dies and the case goes from one step to another, usually in a circular way, although there have been some inline progressive presses.

Progressive presses are used by those who want to load a lot of ammo quickly. But for most handloaders, the single-stage press can do everything needed for a lifetime of service.

Certainly, it’s best for most newcomers to loading to start with a single-stage press. And all of the major companies in the reloading business offer single-stage presses. These include Hornady, Lee, Forster, RCBS and Redding. These companies also offer comprehensive lines of dies.

During the recent pandemic and resultant supply line shortages, components like bullets, powder and primers were hard to get, if they were available at all.

For the most part, components are now more available, albeit at higher prices than in the pre-COVID times. Recent trends indicate that components will be more available in the near future.

Given the extensive numbers of different powders, primers and bullets, it is crucial that handloaders follow established safe recipes. Changes in any of the components can call for quite different recipes.

Makers of powder, presses and dies have established safe loading data that are available, either in their printed loading manuals or on their websites.

Bottleneck brass cases for most modern centerfire hunting cartridges generally call for two dies – one die that resizes and de-primes the case, and a second die that seats the bullet and may or may not also crimp the mouth of the case to hold the bullet firmly.

Straight wall cases like those for most pistol cartridges and some rifle cartridges generally call for three dies.

One of those dies resizes and de-primes the case, a second die flares the mouth of the case slightly to allow easy insertion of the bullet and the third die seats the bullet and crimps the mouth of the case.

Re-priming metallic cases can be done via a priming feature on the press or with a separate priming tool

For shotshells, there are minimally five dies at separate stations on the press. The first die resizes and de-primes the case; the second die station primes the case; the third die station is where the powder is put into the case, the wad is seated and the shot is dropped into the case; the fourth die station is where the crimp is started and the fifth station is where the crimp is completed.

Some shotshell presses have additional dies. For example, on some presses, there is a final die after the crimp die. This die returns the entire shell back to spec, which includes a radius on the outside of the mouth, which helps in feeding the blunt-nose rounds.

For those who do choose to load their own ammo, safety is paramount. It is important to pay close attention to every act when loading, and when in doubt, stop, think and be certain before continuing.

Manufacturers of loading equipment offer the full range of safety measures that need to be followed.

Handloading can be very safe, or it can be dangerous, depending on the person doing the loading. By using safe data and following proper procedures, handloading can be a lot of fun, be very fulfilling and open a whole new world.

Load safely. Shoot straight and often. Bang, bang.